The housing stock in upstate New York, where we primarily work, tends to be older, and many of the older homes need some level of repair. We are seeing a flurry of renovation and repair activity going on in communities large and small. We can’t help but wonder how many of the renovation contractors we see have the required certification from the US Environmental Protection Agency to ensure that their work practices in homes that may contain old lead-painted surfaces have the training certifications required to legally be in business.

Known as RRP Certification, this training has been around for many years, but surprisingly few contractors understand that they live under this requirement. Congress passed the Residential Lead-Based Paint Hazard Reduction Act of 1992, also known as Title X, to protect families from exposure to lead from paint, dust, and soil. The RRP Rule was a part of this legislation. It stands for Renovation, Repair, and Painting, and covers all manner of trades that might work on common home repair projects.

Any home built prior to 1978 is likely to contain lead-based paint, with homes constructed prior to 1940 having a 90% chance of having some form of lead paint. Lead was used for its durability, malleability, as well as its resistance to mold growth. In 1978, a consumer protection act banned the sale of lead in paint products in the US because it was proven to be a hazard to small children, leading to developmental issues among other health effects. Impacts can last a lifetime and treatment can be extremely costly.

Children are primarily exposed lead through hand to mouth activity. They can find lead on or near deteriorated painted surfaces, which creates dust that is ingested. Lead dust can be created by the simple act of closing or opening a window or door that had been painted with lead-based paint, repeated impact, tread wear, weathering, or anything else that may cause a painted surface to become deteriorated. Dust is also generated by demolishing or dismantling components of a home, such as window or door replacement, or tearing out a wall to create an open concept layout in the living spaces of the home. Avoiding exposure is the best option, by far.

The EPA has devised recommended practices for controlling dust exposure in these instances to avoid spreading contaminants throughout the home, and to ensure that when a project is completed by a contractor that the space is returned to the homeowner clean and free of contaminants that could threaten the children living in the home. To ensure that renovation projects do not make a bad situation worse, the EPA requires home improvement contractors and their crews to take classes on how to control any lead-based paint contaminants during construction projects, how to properly clean the spaces that they have been working on, and testing required to document that the space is lead-safe upon completion of the project. Further, the EPA has instituted a schedule of fines for contractors who violate the protocols, or who are unable to produce their training certification documents upon demand.

If you think that the EPA isn’t serious about this issue, you only need to look at a fine they levied last winter. In December, 2020, the EPA fined one of the nationwide building supply and hardware retailers over $20 million for violations discovered in 5 states, after that retailer had sent out uncertified contractors to work on renovation projects for residential customers. Susan Bodine, Assistant Administrator of the EPA Office of Enforcement and Compliance Assurance, noted that this large settlement “will significantly reduce children’s exposure to lead paint hazards.”

Allowable fines under the EPA requirements are $37,500 per DAY per violation in criminal penalties, AND an additional $37,500 in civil penalties – PLUS damages. Fines can mount up fast if you have a good-sized crew working on a job, and damages for lifelong health effects can be in the millions. Even if you are working in a trade that doesn’t touch paint (under normal circumstances), you should get trained and keep your certification easily available.

If you are a contractor, do not expect local code enforcement officials to tell you about these requirements when you pull a building permit. Frankly, it is not their job to do so. Nor are they required to keep records on whether you have the certifications needed. Keeping those records is the job of the contractor.

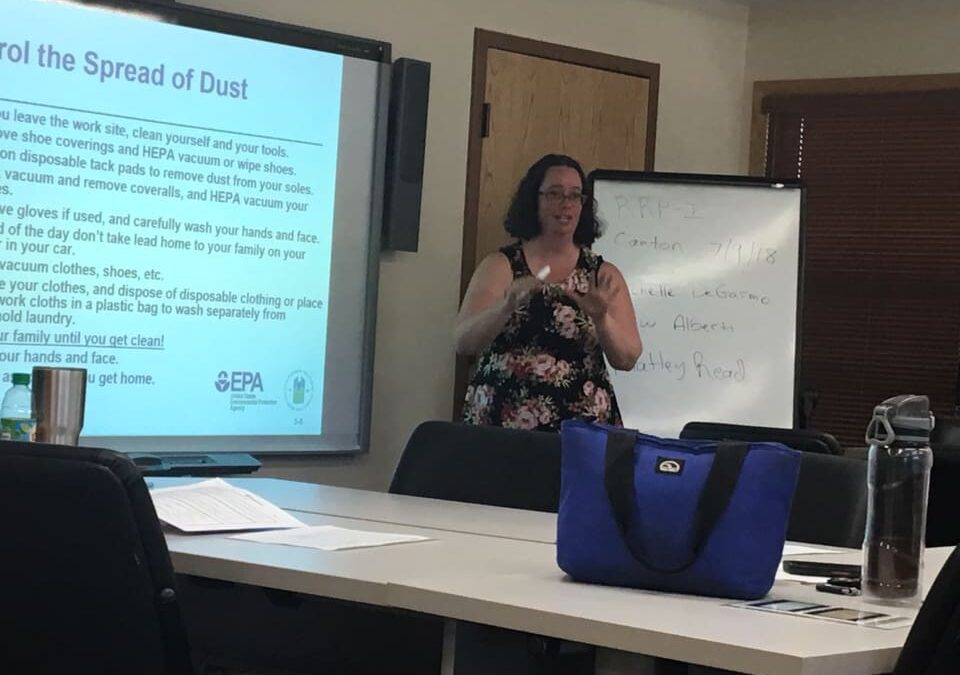

The training programs for compliance with the EPA requirements will cover the important record-keeping requirements to help protect your company if an EPA inspector shows up at your work site. Flatley Read is one of the companies that provides this training, both at our headquarters in upstate New York, and at various locations around the state. Please enquire if you’d like to know more about this training.

The Flatley Read schedule of RRP trainings is found on this website at flatleyread.com/product/rrp-initial/.

A warning to crafty homeowners: It is extremely popular right now to decorate interiors with upcycled projects using old lumber with scabby paint. There are lots of YouTube how-to videos showing craft projects made from old windows, doors, barn siding, and other objects with peeling and faded old paint. In some cases, the crafters leave the paint peeling, while others may sand it lightly to enhance the ‘effect’. In either case, the presence of this old paint will introduce lead paint hazards into your home, even if it is brand new and otherwise lead-safe. The paint dust will end up on your floor, or in your carpets, and present a long term hazard to your children or grandchildren. If you have had renovations completed recently by an RRP-certified contractor, please think twice about undoing all of that contractor’s hard work in giving you a clean, lead-safe home. Your craft project could permanently undo all of that effort.

– The Curmudgeon